The growing demand for sustainable practices in various industries has led to a greater focus on the use of recycled materials. One such innovation is the use of Regenerated rubber in Conveyor Belt Manufacturing

What is regenerated rubber?

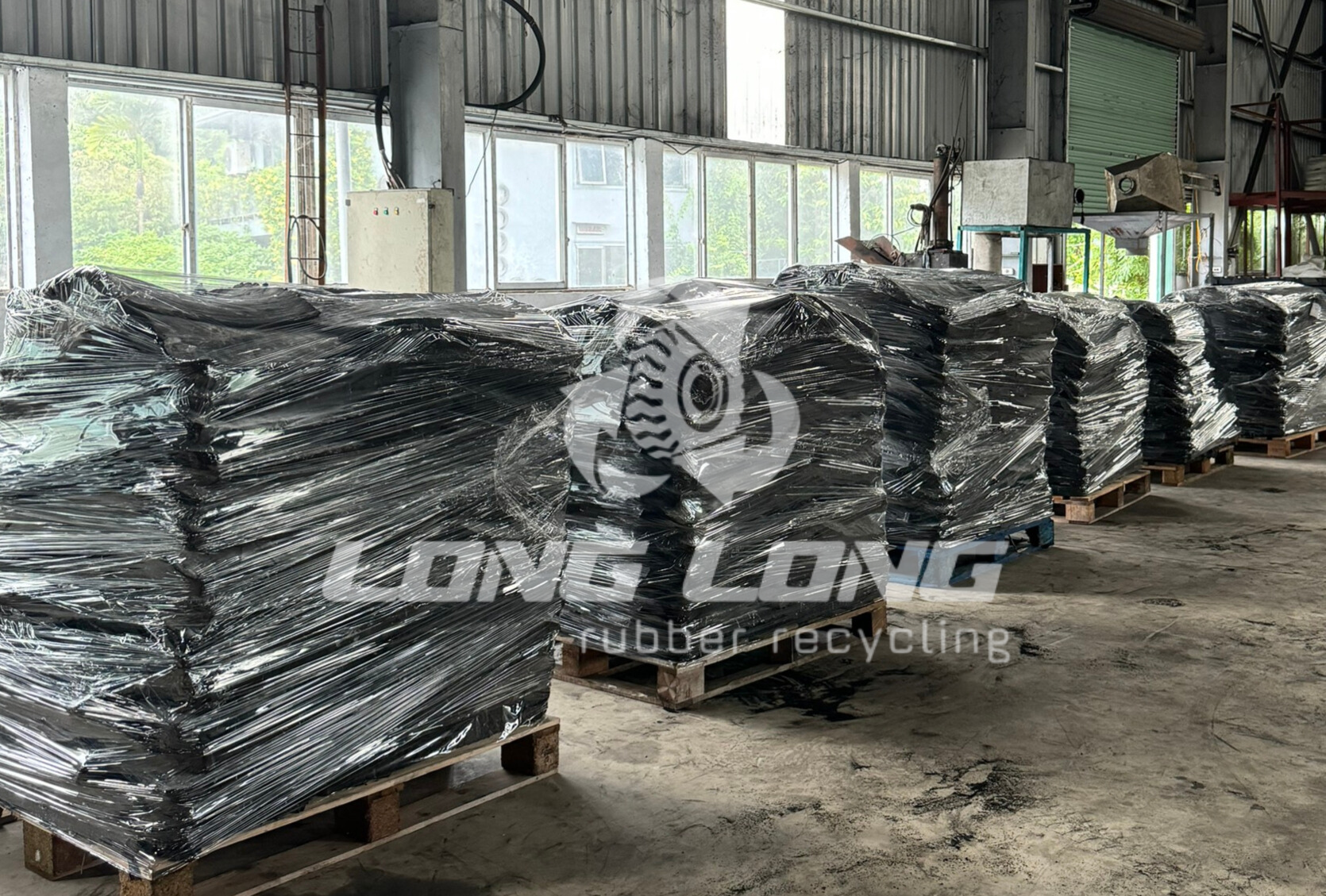

Regenerated rubber is derived from used rubber products such as truck tires, shoe soles, or other industrial rubber. At Long Long, we recycle 100% waste tires. The recycling process involves breaking down these materials and reusing them into new products. Regenerated rubber in Conveyor Belt Manufacturing offers a durable and environmentally friendly alternative to virgin rubber.

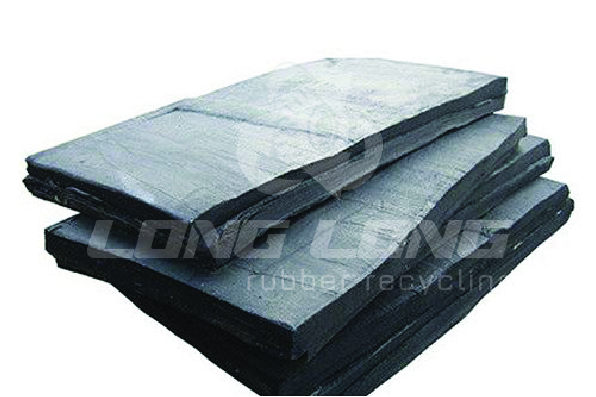

Description:

- Origin: Vietnam

- Brand: Long Long Rubber

- Materials: 100% rubber granules from truck tires

- Color: Black

- Weight: 10kg/sheet

Benefits of using Regenerated rubber in Conveyor Belt Manufacturing

1. Environmental impact: The use of recycled rubber significantly reduces the need for raw materials, thereby conserving natural resources. It also minimizes the environmental footprint by reducing waste and reducing carbon emissions associated with rubber production.

2. Cost-effective: Regenerated rubber in Conveyor Belt Manufacturing is often more affordable than virgin rubber, resulting in lower conveyor belt production costs. This cost efficiency is especially beneficial for industries looking to optimize their budgets while maintaining quality.

3. Durability: Contrary to popular belief, recycled rubber can be as durable and reliable as new rubber when properly treated. It provides the strength and flexibility needed for conveyors used in heavy-duty applications.

The production process of Regenerated rubber in Conveyor Belt Manufacturing

1. Collection and classification: The first step involves collecting used rubber products and classifying them based on quality and type.

2. Shredding and Grinding: The graded rubber is then chopped into smaller pieces and ground into a fine powder or granule.

3. Compounds: Milled rubber is mixed with various additives to enhance its properties, such as durability, flexibility, and abrasion resistance.

4. Molding and vulcanization: The compound rubber is molded into the desired shape and vulcanized to create a strong and durable conveyor belt.

5. Quality Control: Final products undergo rigorous quality control tests to ensure they meet industry standards and performance requirements.

The use of Regenerated rubber in Conveyor Belt Manufacturing is a step towards a more sustainable future. It offers significant environmental benefits, cost savings, and durability, making it an excellent choice for industries looking to adopt environmentally friendly practices. As demand for sustainable products continues to increase, recycled rubber conveyor belts will likely become the standard in various industrial applications. If you are considering incorporating sustainable materials into your manufacturing process, explore the advantages of recycled rubber conveyor belts. Contact us today to learn more about our environmentally friendly conveyor solutions.

main.comment_read_more